Important Qualities of the Welding Inspector

Important Qualities of the Welding Inspector

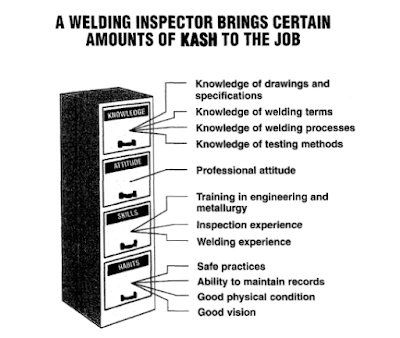

The individual who does welding inspection should possess certain qualities to assure that the job will be done most effectively. Figure 1.2 illustrates

these quali ties.

The first, and perhaps the most important quality,is a professional attitude. Professional attitude is often the key factor for welding inspector success.

Inspector attitude often determines the degree of respect and cooperation received from others during the performance of inspection duties. Included in this category is the ability of the welding inspector to make decisions based on facts so that inspections are fair, impartial and consistent.

If decisions are unfair or show partiality or inconsistency, they greatly affect the inspector’s credibility.

A welding inspector must be completely familiar with the job requirements so that decisions are neither too critical nor too lax.

It is a mistake for the inspector to have preconceived ideas as to a component’s acceptability. Inspection decisions must be based on facts; the condition of the weld and the acceptance criteria specified in the applicable specification must be the determining factors.

Inspectors will often find themselves being “tested” by other personnel on the job, especially when newly assigned to some task.

Maintaining a professional attitude helps overcome obstacles to successful job performance.

Next, the welding inspector should be in good physical condition.

Since the primary job involves visual inspection, obviously the welding inspector should have good vision, whether natural or corrected.

The AWS CWI program requires the inspector to pass an eye examination, with or without corrective lenses, to prove near vision acuity on Jaeger

J2 at 12 in., and complete a color perception test.

Another aspect of physical condition involves the size of some welded structures.

Welds can be located anywhere on very large structures, and inspectors must often go to those areas and make evaluations.

Inspectors should be in good enough physical condition to go to any location where the welder has been.

This does not imply that inspectors must violate safety regulations just to do their duties.

Inspection can often be hampered if not done immediately after welding, because access aids for the welder such as ladders and scaffolding may be removed, making inspection impossible or dangerous.

Within safety guidelines, welding inspectors should not let their physical condition prevent them from doing the inspection properly.

The individual who does welding inspection should possess certain qualities to assure that the job will be done most effectively. Figure 1.2 illustrates

these quali ties.

The first, and perhaps the most important quality,is a professional attitude. Professional attitude is often the key factor for welding inspector success.

Inspector attitude often determines the degree of respect and cooperation received from others during the performance of inspection duties. Included in this category is the ability of the welding inspector to make decisions based on facts so that inspections are fair, impartial and consistent.

If decisions are unfair or show partiality or inconsistency, they greatly affect the inspector’s credibility.

A welding inspector must be completely familiar with the job requirements so that decisions are neither too critical nor too lax.

It is a mistake for the inspector to have preconceived ideas as to a component’s acceptability. Inspection decisions must be based on facts; the condition of the weld and the acceptance criteria specified in the applicable specification must be the determining factors.

Inspectors will often find themselves being “tested” by other personnel on the job, especially when newly assigned to some task.

Maintaining a professional attitude helps overcome obstacles to successful job performance.

Next, the welding inspector should be in good physical condition.

Since the primary job involves visual inspection, obviously the welding inspector should have good vision, whether natural or corrected.

The AWS CWI program requires the inspector to pass an eye examination, with or without corrective lenses, to prove near vision acuity on Jaeger

J2 at 12 in., and complete a color perception test.

Another aspect of physical condition involves the size of some welded structures.

Welds can be located anywhere on very large structures, and inspectors must often go to those areas and make evaluations.

Inspectors should be in good enough physical condition to go to any location where the welder has been.

This does not imply that inspectors must violate safety regulations just to do their duties.

Inspection can often be hampered if not done immediately after welding, because access aids for the welder such as ladders and scaffolding may be removed, making inspection impossible or dangerous.

Within safety guidelines, welding inspectors should not let their physical condition prevent them from doing the inspection properly.

Comments

Post a Comment